Description

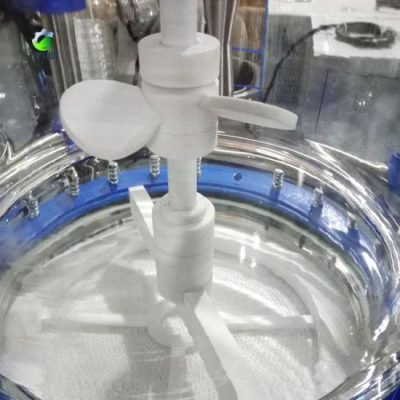

Chemical and Active Pharmaceutical Ingredients are frequently processed as powders so that, after the reaction crystallisation of the solution and separation of solid and liquid materials becomes necessary. Thus Global has developed Agitated Glass Nutsche Filter made from Borosilicate Glass.

Global Nutsch filters can easily be combined with our reactors for solid / liquid separation after the synthesis. The inert materials allow safe processing in an inert atmosphere of a wide range of solvents and acids in a completely sealed glass system under full vacuum. Suitable filter is used to separate the solid particles of the slurry, forming a filtered cake, while the filtrate can be collected from the outlet valve in the bottom.

The cake is removed easily from the top by opening the cover and lowering the glass filter vessel, which is fixed to the lifting device.

Glass Nutsche Filter consists of :

- Glass filter vessel

- Manual stirrer in stainless steel, Hastelloy or with inert coating

- ATEX stirrer drive with adjustable stirrer speed

- Heating jacket (drying)

- PTFE bottom plate with filter cloth

- Mobile stainless steel frame with lifting device

Application

⦁ Chemical synthesis

⦁ Extraction / evaporation

⦁ Purification / crystallization

⦁ Separation

⦁ cGMP API production

⦁ Peptide synthesis

⦁ Process development

⦁ Scale-up

⦁ Cryogenic reactions

⦁ Pilot plant /kilo lab

Glass Nutsche Filter Features

- Effective Filtration – Maximized filtering efficiency due to large filtration surface area.

- Leak-proof Mounting System – Unique Filter Housing Prevents Leakage.

- Easy Adjustment and Centering

- Convenient Handling Cart can be moved comfortably to different locations.

- Nozzle Orientation – can be arranged to suit client’s needs. E.g Stirrer handle, Feed pipe, Spray nozzle.

- Filter housing – Leak-proof mounting system, high sealing performance.

- Filter : PEEK, PTFE,PP. Mesh Size: 1- 5,100µm.

- Stirring apparatus – Locking, multi-directional stirring device maintains a uniform cake (upto 150mm).

- Customized configuration are also available.

- Can apply the vacuum from the bottom to speed up the filtration.

| DESCRIPTION | 5 L | 10 L | 20 L | 50 L | 100 L |

|---|---|---|---|---|---|

| Nominal Diameter | 150 DN | 225 DN | 300 DN | 400 DN | 450 DN |

| Glass material | High borosilicate glass, Temperature range: -60℃~300℃ | ||||

| Filtration Area | 0.025 | 0.045 | 0.06 | 0.12 | 0.18 |

| Jacket Design Pressure | 0.5 bar(g) | 0.5 bar(g) | 0.5 bar(g) | 0.5 bar(g) | 0.4 bar(g) |

| Operating Pressure | FV / ATM | ||||

| Operating Temperature | -30 to +200° C | ||||

RELATED CONTENT

This product belongs to the solution

Other Products