Description

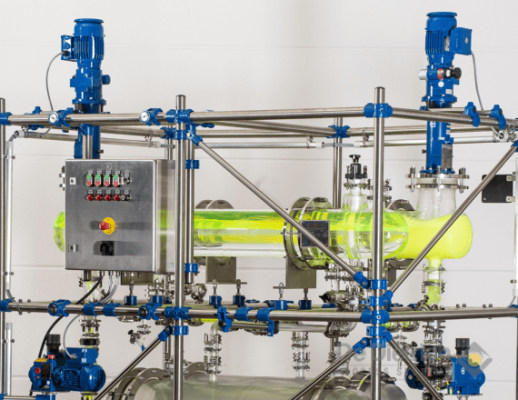

Mixer-settlers are commonly used for liquid/liquid solvent extraction applications that typically operate in continuous mode. Their name is derived from the two stages that make up the process – the first stage that mixes the two liquid phases together to accomplish mass transfer, and the second stage that uses gravity to naturally separate and settle the phases.

The mixer and settler are essentially two separate components that are integrated to act as one system. In the simplest of arrangements, the mixer vessel contains an agitator that is in contact with the feed solution (heavy phase) and solvent (light phase) to thoroughly mix the phases (if more contact time is required, the feed rate is decreased, or multiple mixer-settlers/stages are employed).

From there, a pumping turbine transfers the emulsion to the settler. The settler, which is located downstream from the mixer to allow the heavy phase and light phase liquids to separate by gravity. The settler may incorporate coalescer plates to aid in the separation of phases and break down of foam. Coalescers can be several different configurations (plate / formed plate/ structured packing).

Additionally, the mixing and settling zones are separated by a weir, or barrier, to avoid back-mixing. Once the process is complete, the liquids can be removed separately.

Glass Mixer Settler consists of :

- Mixer – Settler battery

- Metering pumps for light and heavy phase for volume and ratio setting/ flow adjustment

- Feed & collector vessels for light and heavy phase

- Agitator for mixer vessel

- Stainless steel structure

- Temperature and feed indicator panel

Application

- Extraction (moving an ion of interest from an aqueous phase to an organic phase),

- Washing (rinsing entrained aqueous contaminant out of an organic phase containing the ion of interest), and

- Stripping (moving an ion of interest from an organic phase into an aqueous phase).

Glass Mixer Settler features

- Exceptional settler design for minimized hold-up combined with maximal flexibility of phase ratio

- Any adaptation possibilities (temperature, pH, …) in drain line and settler of light and heavy phase

- Mixer pump for optimized drop generation (size, size variation) combined with full feed suction capacity

- Tempered jacket and feed pre-heating for scale-up for temperized and non-temperized systems

- Product phase collection via gravity flow in receiver vessels

RELATED CONTENT

This product belongs to the solution

Other Products