Description

Heat transfer is an integral component in virtually all processes. Depending on the equipment usage requirements, heat exchangers, also called condensers, coolers, and boilers, can perform various functions.

Shell & tube heat exchangers offer large surface area in combination with efficient heat transfer and compactness.

GLOBAL are the pioneers in the field of glass shell and tube heat exchangers in India and their product has a wide market acceptability.

Advantages of Shell and Tube Heat Exchanger Over Conventional Coil Type Heat Exchangers:

- The overall heat transfer coefficient in shell and tube heat exchanger is about 3 times higher than in coil type heat exchanger.

- The pressure drop in shell and tube heat exchanger is minimal compared to 2-3 kg/cm2 in coil side of coil type heat exchanger.

- For requirement of higher heat transfer areas shell and tube heat exchanger is the only alternative.

| Material Of Construction of Shell & Tube Heat Exchanger | ||||

|---|---|---|---|---|

| Model | Shell | Tube | Header | Duty |

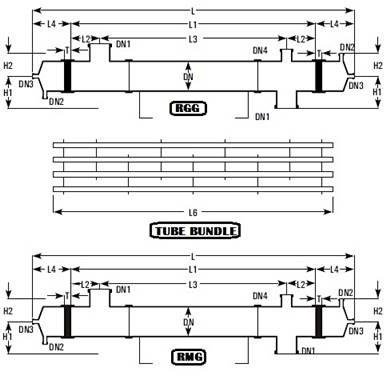

| RGG | Glass | Glass | Glass | For heat transfer between two aggressive media. |

| RGM | Glass | Glass | Steel/FRP | For heat transfer between aggressive media in shell & non-aggressive media in tubes. |

| RMG | Steel/FRP | Glass | Glass | For heat transfer between aggressive media in tubes & non-aggressive media in shell |

Shell & Tube Heat Exchangers features

- Universal Corrosion Resistance

- Outstanding heat transfer

- Space-saving arrangement by installing in Horizontal or Vertical position

- Simple replacement of inner tubes for repair and cleaning

- Low Maintenance cost

- Standard Shell & Tube Heat Exchangers are available in range of 2.5 m2 to 25.0 m2

| Cat.Ref. | 6/3 | 6/4 | 6/5 | 6/6 | 9/6 | 9/8 | 9/10 | 9/12 | 12/12 | 12/16 | 12/21 | 12/25 |

| RGG/RMG | ||||||||||||

| Area (m2) | 3 | 4 | 5 | 6 | 6 | 8 | 10 | 12 | 12 | 16 | 21 | 25 |

| DN | 150 | 225 | 300 | |||||||||

| DN1 | 80 | 100 | 150 | |||||||||

| DN2 | 50 | 80 | 80 | |||||||||

| DN3 | 25 | 40 | 40 | |||||||||

| DN4 | 50 | 50 | 50 | |||||||||

| H1 | 175 | 250 | 300 | |||||||||

| H2 | 150 | 200 | 250 | |||||||||

| L | 2500 | 3100 | 3700 | 4300 | 2620 | 3220 | 3820 | 4520 | 2550 | 3150 | 3950 | 4550 |

| L1 | 1900 | 2500 | 3100 | 3700 | 1900 | 2500 | 3100 | 3800 | 1800 | 2400 | 3200 | 3800 |

| L2 | 150 | 150 | 150 | 150 | 225 | 225 | 225 | 225 | 225 | 225 | 225 | 225 |

| L3 | 1600 | 2200 | 2800 | 3400 | 1450 | 2050 | 2650 | 3350 | 1350 | 1950 | 2750 | 3350 |

| L4 | 250 | 250 | 250 | 250 | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 |

| L5 | 125 | 125 | 125 | 125 | 175 | 175 | 175 | 175 | 175 | 175 | 175 | 175 |

| L6 | 1980 | 2580 | 3180 | 3780 | 2000 | 2600 | 3200 | 3900 | 1930 | 2530 | 3330 | 3930 |

| T | 50 | 60 | 75 | |||||||||

| No. of Tubes | 37 | 73 | 151 | |||||||||

| No. of Baffles | 11 | 15 | 19 | 23 | 7 | 9 | 13 | 17 | 5 | 7 | 9 | 11 |

RELATED CONTENT

This product belongs to the solution

Other Distillation & Evaporation Products