Description

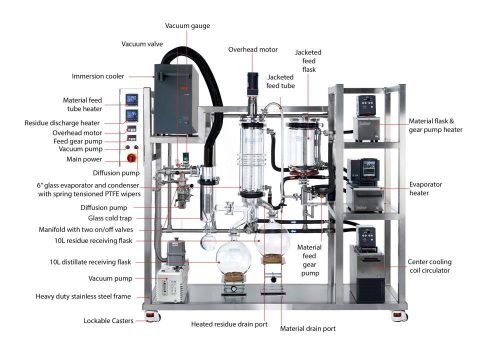

Molecular Distillation/Short Path Distillation is a comparatively new separation technology. It can separate liquid-liquid mixture under temperature that is far lower than boiling point by the difference of mean free path of molecules under high vacuum condition. Such separation is difficult or unable to achieve on normal distillation equipments. Molecular Distillation is especially suitable to separate substances of high boiling point, heat sensitive and easy to be oxidized.

Bench Top Glass Reactors consists of :

⦁ Stand with base, drip tray, support rods, bosses and all clamps

⦁ Glass Reaction Vessel Lid

⦁ Vessel FEP O-ring seal and PTFE Collar

⦁ Stainless Steel Drip Tray

⦁ Vessel to Manifold Insulated Hoses with Quick-Release Connections

⦁ Lower Inlet Manifold + Drain

⦁ Upper Outlet Manifold + Vent

⦁ PTFE Stirrer Guide and Coupling

⦁ Two stainless steel Vessel Support Collars

⦁ Locking Rod for Support Rod Bosses

Application

- Enzymes, Proteins, vitamins, etc.

- Fouling mixtures

- Aromatics Pharmaceuticals and more

Short Path Distillation unit features

- Removal of trace volatiles from heat sensitive mixtures

- Suitable for heat sensitive mixtures with high boiling point

- Minimal pressure drop due to internal condenser

- Uniform thin film formation by PTFE wipers

- Shorter residence time compared to other evaporation systems

- Process visibility due to all glass design

- Operating range up to 200 °C

| Model | GMD-60 | GMD -80 | GMD -100 | GMD -150 | GMD -200 | GMD -230 |

|---|---|---|---|---|---|---|

| Effective Evaporation Area (M2) | 0.05 | 0.1 | 0.15 | 0.25 | 0.35 | 0.5 |

| Inner Condensation Area (M2) | 0.1 | 0.18 | 0.3 | 0.4 | 0.5 | 0.65 |

| Barrel Outside Diameter (mm) | 60 | 80 | 100 | 150 | 200 | 230 |

| Feeding Vessel (L) | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 |

| Normal Process Capacity* (L/H) | 2 | 4 | 6 | 8 | 15 | 25 |

| Rotation Speed (RPM) | 350 | 350 | 300 | 300 | 200 | 200 |

| Stirrer seal | Magnetic | |||||

| Maximum temperature | +200°C in jacket with PTFE wiper | |||||

| Operating pressure | 0.001 mbar (abs.) to atm | |||||

| Operating jacket pressure | Up to +0.5 barG (+0.05 MPa) | |||||

RELATED CONTENT

This product belongs to the solution