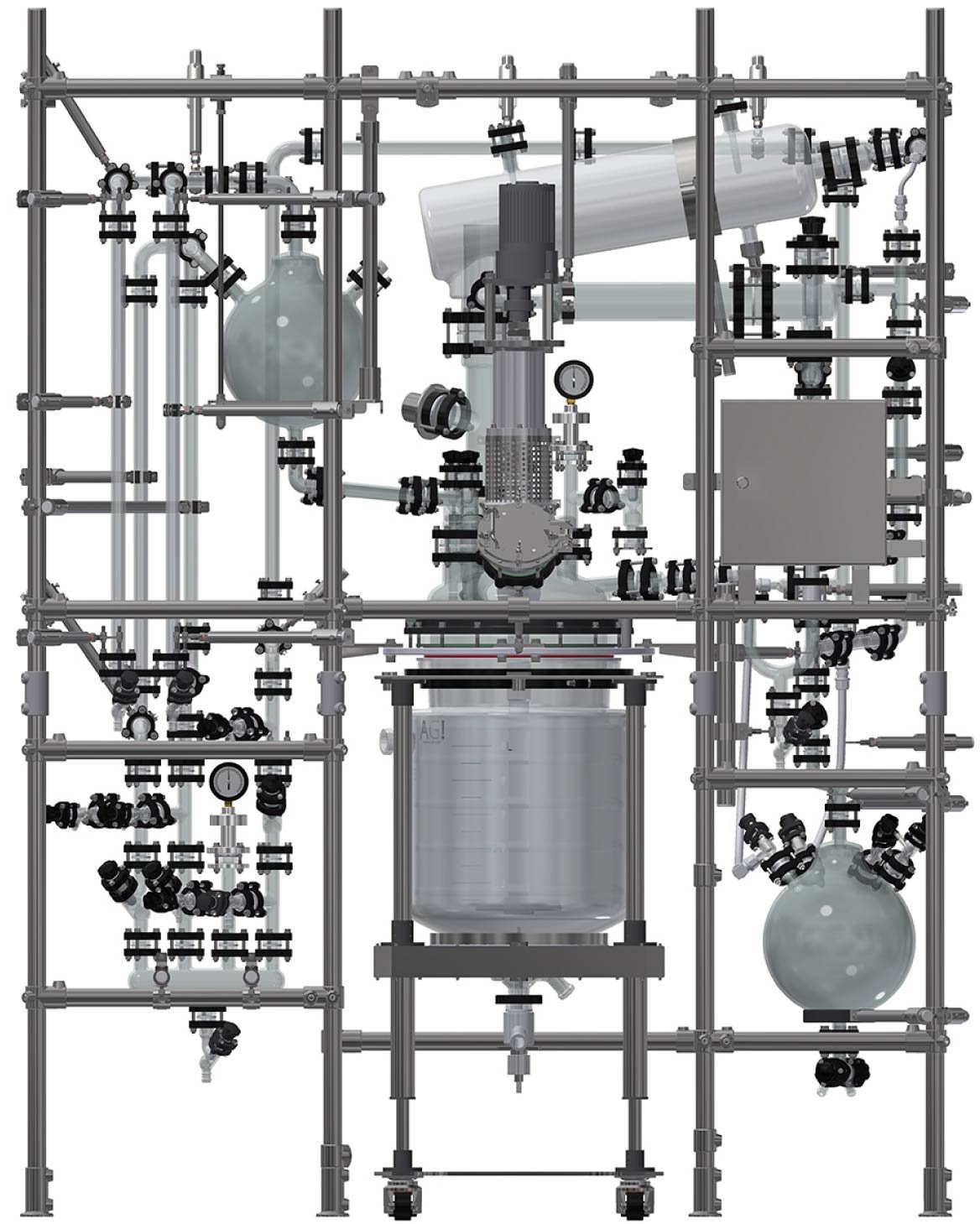

Description

Global Universal Reactor is a very adaptable system with a variety of features that meets the needs of most reaction processes including distillation, phase separation and dosing. We pour our knowledge and experience into its construction, resulting in a multifunctional chemical processing system that offers excellent value. Each system is built to order and so can be totally configured to meet your specific process needs.

Universal Reactors consists of :

- Triple / Double walled reactor

- Graduated feed vessels with control valve

- Gas introduction (Nitrogen purging and active gas)

- Azeotropic distillation phase separator

- Twin receiver system for distillate without breaking vacuum

- Coil type Condenser and product cooler

- Vapour column with different options of packing material

- Compact and sturdy Skid designed as per space constraints

- Instrumentation with indication panel

- Vacuum connection incl. pressure release valve and bursting disc

- IQ/OQ/DQ documentation on request

Application

- Chemical synthesis

- Extraction / evaporation

- Purification / crystallization

- Separation

- API manufacturing

- Peptide production

- Process development

- Scale-up

- Cryogenic reactions

- Small scale production

- Pilot plant / kilo lab

Universal Reactor Features

- Multipurpose reactor with various customisable functionalities

- Vessel capacity up to 100 L Triple wall

- All glass body that allows visual monitoring of processes

- Suitable for continuous industrial processes

- Wide process temperature range; -60 °C to +200 °C

- ZERO Hold Up Valve with Temperature Sensing

- Certificates for material in contact with product

| DESCRIPTION | 20 L | 50 L | 100 L | 200 L |

|---|---|---|---|---|

| Reactor Nominal Capacity | 20 L | 50 L | 100 L | 200 L |

| Glass material | High borosilicate glass, Temperature range: -60℃~300℃ | |||

| Heat Exchanger | 0.35 | 0.5 | 1.5 | 2.5 |

| Jacket Design Pressure | 0.5 bar(g) | 0.5 bar(g) | 0.5 bar(g) | 0.4 bar(g) |

| Vessel Design Pressure | 0.8 bar(g) | 0.6 bar(g) | 0.5 bar(g) | 0.4 bar(g) |

| Plant Working Temperature | -60 to +200° C | |||

| Plant Working Pressure | 0.7 bar(g) | 0.5 bar(g) | 0.4 bar(g) | 0.3 bar(g) |

| Safety Valve | Yes | Yes | Yes | Yes |

| Feed Vessel | 5 L | 10 L | 20L | 50L |

| Azeotropic Vessel | 3 L | 5 L | 10L | 20L |

| Receiver Vessel | 2 × 10 | 2 × 20 | 2 × 50 | 2 × 100 |

| Vapour Column | 50 | 80 | 100 | 150 |

| Rupture Disc | 0.5 bar(g) | |||

| Stirrer Rotation Speed | 10 to 250 rpm | |||

RELATED CONTENT

This product belongs to the solution