Description

Thin Film Evaporator (also known as Wiped Film Evaporator) is ideal for separating volatile components from heat sensitive, viscous and fouling chemical mixtures. Thin film, under low pressure, reduces the boiling point of chemical components, as well as the hydrostatic pressure, resulting in the evaporation of volatile fraction at low temperatures. The PTFE wipers form a thin film on the evaporation column and push the film downwards with every rotation. This causes the heat-sensitive components to experience short residence time on the evaporation area and minimal thermal degradation.

The all-glass design of our Thin Film Evaporator allows for continuous visual monitoring, and the adjustable feed rate provides control over film formation.

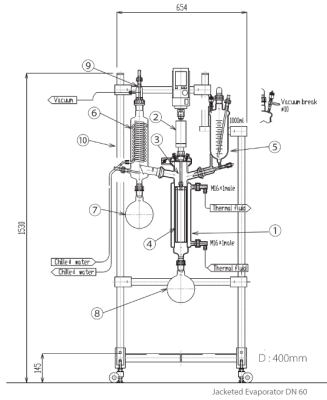

Wiped Film Evaporator consists of :

- PTFE rotating wiper with variable drive

- Feed pump and vacuum pump

- Receivers for high and low boiling components

- Digital display of process parameters

- Compact and sturdy Skid designed as per space constraints

Application

- Methyl ester evaporation

- Glycerine evaporation

- Lecithine drying

- pharmaceutical intermediates concentration

- solvent stripping in polymer industry (isocyanates, cyanoacrilates, etc.)

Wiped Film Evaporator Features

- Bulk removal of volatiles from heat sensitive mixtures.

- Shorter residence time compared to other evaporation systems

- Uniform thin film formation by PTFE wipers

- Reliable Temperature control

- Process visibility due to all glass design

- High degree of vacuum due to magnetic sealing

- Stand with castors for mobility

| DESCRIPTION | DN60 | DN100 |

|---|---|---|

| Jacketed Evaporator | ID 60 mm Evaporation Surface Area: 0.05 m2 | ID 100 mm Evaporation Surface Area: 0.1 m2 |

| Magnetic Seal with Cover | Torque: 1.1 N.m, Cover: SS316 | |

| Stirrer Shaft | SS316 | |

| Wiper | PTFE Wiper: +200 oC (Polybenzimidazole: +300 oC) | |

| Feed Vessel | Feed Vessel: 1000 mL Vent Valve: ф10 Thermometer Pocket SQG 14/25, ф8, 245(L) Cap SQG 29/32 Needle Valve, NGTV-12L | Feed Vessel: 2000 mL Vent Valve: ф10 Thermometer Pocket SQG 14/25, ф8, 330(L) Cap SQG 29/32 Needle Valve, NGTV-12L |

| External Condenser | Thermal Transfer Area: 0.1 m2 Thermometer Pocket: SQG 14/25, ф8 Water Connectors x 2: ф8 | Thermal Transfer Area: 0.2 m2 Thermometer Pocket: SQG 14/25, ф8 Water Connectors x 2: ф8 |

| Receiver for High Molecular Weight | 1000 mL Borosilicate glass 3.3 | 2000 mL Borosilicate glass 3.3 |

| Receiver for Low Molecular Weight | 1000 mL Borosilicate glass 3.3 | 2000 mL Borosilicate glass 3.3 |

| Adapter | Adapter: SQG 34/45, SQG 14/25 Ø 12 mm for vacuum connection Thermometer Pocket: SQG 14/25, 8 mm NW available as Option |

|

| Structure | W 654 x D 400 x H 1530 mm SS + Epoxy Coating |

|

RELATED CONTENT

This product belongs to the solution